Hey everyone! It's me Shouq. This is the first lab report for an Industrial Engineering class called Operational research / optimization - OR1 - IE335 which I took in Fall 2017 in the American University of the Middle East (AUM) in Kuwait.

Abstract

The objective of this report is to show the

work in how to find the cost-minimizing pattern of assembly across three plants

that Ford Company has using the operational research method. First, an introduction

regarding the problem is provided with every detail regarding it. Then the

decision variables are identified as well as the objective functions and the

constraints of the problem. After that the final linear programming formulation

will be presented and explained. Also, the problem is solved using Excel solver

to find the answer of the linear programming problem. Finally, a sensitivity

report is presented as well as a what-if analysis.

Keywords: Ford, Plants,

problem, operational, research, sensitivity, what-if, analysis.

Introduction

A company called Ford has three different assembly plants that are

placed in different places all over the country. Plant number one is located in

the state of Ohio. The requirement to make one automobile in plant number one

is 2 hours of labor as well as a 1 hour of machine time. When it comes to plant

number 2, it is located in the state of California. It requires 1.5 hours of

labor and 1.5 hours of machine time in order to assemble one automobile.

Finally, planet number three is located in the state of Tennessee. It was built

in 1981. And in order to make one automobile in planet number 3, we will need

1.1 hours of labor and 2.5 of machine time as well. All of that is shown in

Table 1.

Labor per day

|

Machine time per day

|

|

Plant Number One

|

2 hours

|

1 hour

|

Plant Number Two

|

1.5 hours

|

1.5 hours

|

Plant Number Three

|

1.1 hours

|

2.5 hours

|

|

The company pays $30 for every hour of labor. It also pays $10 for

every hour of machine time per day to assemble one automobile. Every plant has

different capacity of machine work for every single day. When it comes to the

first plant, it has a daily capacity of 1,000 hour of machine time. On the

other hand, the second plant has a daily capacity of machine time that is equal

to 900 hours. And the highest daily capacity of machine time is in the third plant

that is equal to 2,000 hours. The manufacturer of Ford Company has a daily goal

of assembling 1,800 automobiles.

Problem formulation

Decision variables

·

X1: Number of automobile products that are

produced by plant number 1.

·

X2: Number of automobile products that are

produced by plant number 2.

·

X3: Number of automobile

products that are produced by plant number 3.

Objective function

Min Z = [[(30)(2)

+ (1)(10)] X1 + [(30)(1.5) + (10)(1.5)]

X2 + [(30)(1.1) + (10)(2.5)] X3]

Equation

1

For the objective function; it is minimization where

we minimize the pattern of assembly across three different plants. From

Equation 1 above, Z is the numbers of hours of labor multiplied by 30$ that is

the amount the company is paying for labor. Then adding it to the numbers of

hours of machine time multiply by $10 which is the amount the firm is willing

to pay for the machine time per hour with the number of product automobile by

the three different plants that we have. (Xi = 1, 2, 3)

Subject

to

·

X1 + X2 + X3 >= 1800

Equation 2

Equation 2 is the equation of the first constraint. We

will sum up the number of product automobile by plant 1, 2, and 3 as well. We

know that the sum of all Xi where i = 1, 2, 3 should be greater than or equal

to 1800. 1800 is the daily target of number of automobiles that the

manufacturer of Ford Company has.

·

0.5 X1

+ X1 =< 1000

Equation 3

Equation 3 is the equation of the second constraint.

It represents the number of automobile products that are produced

by plant number one that is X1. We divided

the number of labor with the number of machine times in plant number one and we

added them with the number of automobile products that

are produced by plant number 1 without

dividing.

·

(1.5 / 1.5) X2 + X2 =< 900

Equation 4

Equation 4 is the equation of the third constraint. It

represents the number of automobile products that are produced

by plant number two which is X2. We divided

the number of labor hours to the number of machine times that are required when

it comes to plant number two. Then we add it to the number of

automobile products that are produced by plant number 2. The amount of all of

that added together should be less than or equal to 900. 900 are the number of

hours that is the daily capacity of machine time in the second plant.

·

(1.1 / 2.5) X3 + X3 =< 2000

Equation 5

Equation 4 is the equation of the forth constraint. It

represents the number of automobile products that are produced

by plant number three which is X3.

We divided the number of labor hours to the number of machine times that are

required when it comes to planet number three. Then we added it all to the

number of automobile products that are produced by plant number three. The

amount of all of that added together should be less than or equal to 2000. 2000

is the number of hours that is the daily capacity of machine time in the second

plant.

·

X1, X2,

X3 >= 0

Equation 6

Equation

6 is considered to be a non-negativity constraint. For the values of X1, X2 and X3 are supposed to be

zero or a positive number that is greater than zero as it does not make sense

to produce negative numbers of products, so zero is considered to be the smallest

number for production which means producing no products. Also, it can be any

number that is more than zero.

Conclusion

The final Linear Programming Formulation is

Figure 1: Final LP

formulation

Methodology

First, we will start by providing

the Excel Solver solution of the previously mentioned LP formulation. Then we

will continue by finding and presenting the sensitivity analysis as well. Finally,

we will end it with the what-if analysis. In each part of the solutions we will

provide an explanation of what we did and how did we get that specific answer.

Excel

Figure2: The

table of the solution in Excel

As

showed in Figure 2, we defined the objective function (Z) that is minimizing the pattern of assembly across three different plants.

Z is the numbers of hours of labor multiplied by 30$ that is the amount the

company is paying for labor. Then adding it to the numbers of hours of machine

time multiply by $10 which is the amount the firm is willing to pay for the

machine time per hour with the number of product automobile by the three

different plants that we have. (Xi = 1, 2, 3)The first number in the third row is equal to 70, and

we got it by multiplying 30 by 2 ten adding it to 1 multiplied by 10. This all

was explained by details in the problem formulation part. The

final result of objective function is 105222 that got transformed to 411 when

we changed the decimal point of the answer to zero. The answer was found using Excel

solver. Moreover, we defined the constraints as c1, c2, c3, and c4. The first constraint is the sum of everything should

be greater than or equal to 1800. 1800 is the daily target of number of

automobiles that the manufacturer of Ford Company has. We got the final result of this constraint by using

Excel solver. The second constraint represents the number of

automobile products that are produced by plant number one. We got the final result of this constraint by using

Excel solver and it should be less than 1800. The third constraint represents the

number of automobile products that are produced by plant number two, and it should be less than 900. The forth constraint

represents the number of automobile products that are produced

by plant number three, and it should

be less than 2000. Finally, we used the Excel solver to get the values for the

constraints and the value of (Xi).

Sensitivity analysis

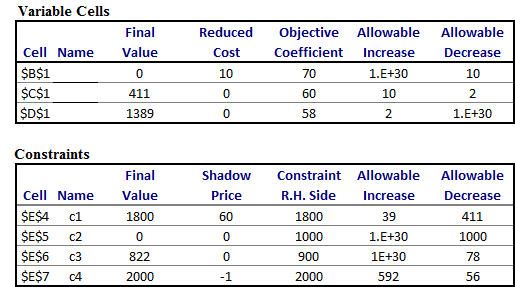

Figure 3: The

table sensitivity analysis

The optimal

solution of the earlier linear programming problem is to order zero automobile products that are produced by plant number one as well

as 411 automobile products that are produced by plant number two. Also, we get

to order 1389 automobile products that are produced by plant number three. The

solution mentioned above in Figure 3 has1800 that is daily goal of assembling

1,800 automobiles that is assigned by the manufacturer of Ford Company.

What-if analysis

What is the cost of assembling one

extra automobile given that the current output level of 1,800 automobiles?

Would the answer be different if the goal of the production was only 8,000

automobiles? Why or why not?

The answer will be

different if we changed the production target from 1,800 to 8,000 of the cost

of assembling one extra automobile will be equal to 6,200. Also, from the

previous data in Figure 2 we notice that 6,200 are out of range.

A team of production

specialists has indicated that the auto manufacturer can achieve efficiencies

at its Bakersfield plant by reconfiguring the assembly line. The

reconfiguration has the effect of increasing the productivity of the labor at

this plant from 1.5 hours to 1.2 hour per automobile. By how much will the

firm’s costs fall as a result of this change, assuming that it continues to

produce 1,800 automobiles?

We will start by rewriting the equation. Z = [[(30)(2)

+ (1)(10)] X1 + [(30)(1.2) + (10)(1.5)] X2 + [(30)(1.1) + (10)(2.5)] X3] which is

simply

Z = [70 X1 + 51 X2 + 58 X3], so by X1, X2, X3 substation we

will have the following equations:

^

Z = [70 X1 + 51 X2 + 58 X3] - [70 X1 + 60

X2 + 58 X3]

= [70 *

0 + 51 * 411 + 58 * 1389] - [70 * 0 + 60

* 411 + 58 * 1389]

= -3699.

The

cost will fall by 3699.

What

if 1,900 auto are produced, by how much the costs will increase?

Z new =

105,222 + (60 * 1,900) = 219,222. And 219,222 - 105,222 = 114000. So the cost

will increase by 114000.

What if labor costs $35 per hour in

Bakersfield, California, what would be the new solution?

Z

= [[(30)(2) + (1)(10)] X1 + [(35)(1.5)] X2 + [(30)(1.1) + (10)(2.5) X3], which

is simply Z = [70 X1 + 67.5 X2 + 58 X3] and since the

coefficient of X2 has changed so d2 = 67.5 – 60 = 7.5, which means it increased.

In addition the Z new will be equal to [70 X1 + 67.5 X2 + 58 X3],

and by substation; Z new = [70 * 0 + 67.5 *

411 + 58 * 1389]; the final

result within the range.

Results and discussion

The first, second

and third assembly plants that Ford Company has require 2 hours, 1.5 hours and

1.1 hours of labor. Also, they require 1 hour, 1.5 hours, and 2.5 hours of machine

time to assemble one automobile. The objective function of the problem was

defined where Z is minimizing the pattern of assembly across the three

different plants. In order to make sure that we understood every single part

correctly, in every part we wrote an explanation of what we did, how did it,

and specified everything as well. The company has goal that we are trying to

achieve which is to assembling 1,800 automobiles. By solving the problem in

Excel, we got provided the solution of the problem using the previously

mentioned linear programming formulation where Z was equal to find the number

from the Excel table. At the end, we found the what-if analysis where if we

changed the production target from 1,800 to 8,000 the cost of assembling one

extra automobile will be equal to 6,200. Also, from the previous data in Figure

2 we notice that 6,200 will be out of provided range that is not acceptable.

Conclusion

In

conclusion, in the project we talked about a company called Ford that has three

different assembly plants. The assembly plants are placed in different location

all over the country with different capacity of machine times for each one of

them. We also wrote a description regarding the problem we had to find a

solution for. After that we found the linear programming formulation of the

problem and solve it using Excel Solver. We also found the sensitivity report of

the Ford Company problem and we presented a what-if analysis as well.

References

Sensitivity Analysis in Excel. (2016). Excel Easy. Retrieved 29

November 2017, from http://www.excel-easy.com/examples/sensitivity-analysis.html

The students who worked in this lab report are

- Shouq Alansari

- Hanan Akbar

- Manal Al-Mutairi

- Nour Almuwai

- Reem Almertiji

Knowing that not all students in the group have put equal efforts on this lab report. Some students worked harder than others, and it is normal when it comes to working on groups.

Things to learn from this lab report: